Frequently Asked Questions How To Install Choosing Your Tubing Selecting Your Fittings

How to Measure your Filament

Our XS Series Bowden Tubing utilizes an extra tight 1.9mm +/- 0.05 internal diameter, making it extremely important to use filament not larger than 1.8mm in diameter. Almost all filament is spec'd at 1.75 +/-0.03 to +/- 0.05 on paper, but we have found that in the real world many filaments are out-of-spec.

This article is written for 1.75mm filaments. For 2.85mm filaments, the same things are true, but note that the numbers will be different.

The first thing you will need is a digital caliper. This is an indispensible tool to have, for 3D printing in general, so you're going to want to pick one up anyway if you haven't already.

You can get a decent set of digital calipers online for around the cost of a roll of filament. Of course there are much better and more expensive options available, if you want to make the investment. We also like analog dial calipers, because they never run out of battery, but they aren't as easy to read.

You're going to want to unroll a couple meters of filament, and take several measurements along the way, looking for thick spots. At each spot, you are going to take two measurements. To get the most accurate results, perform each one a few times and average the numbers.

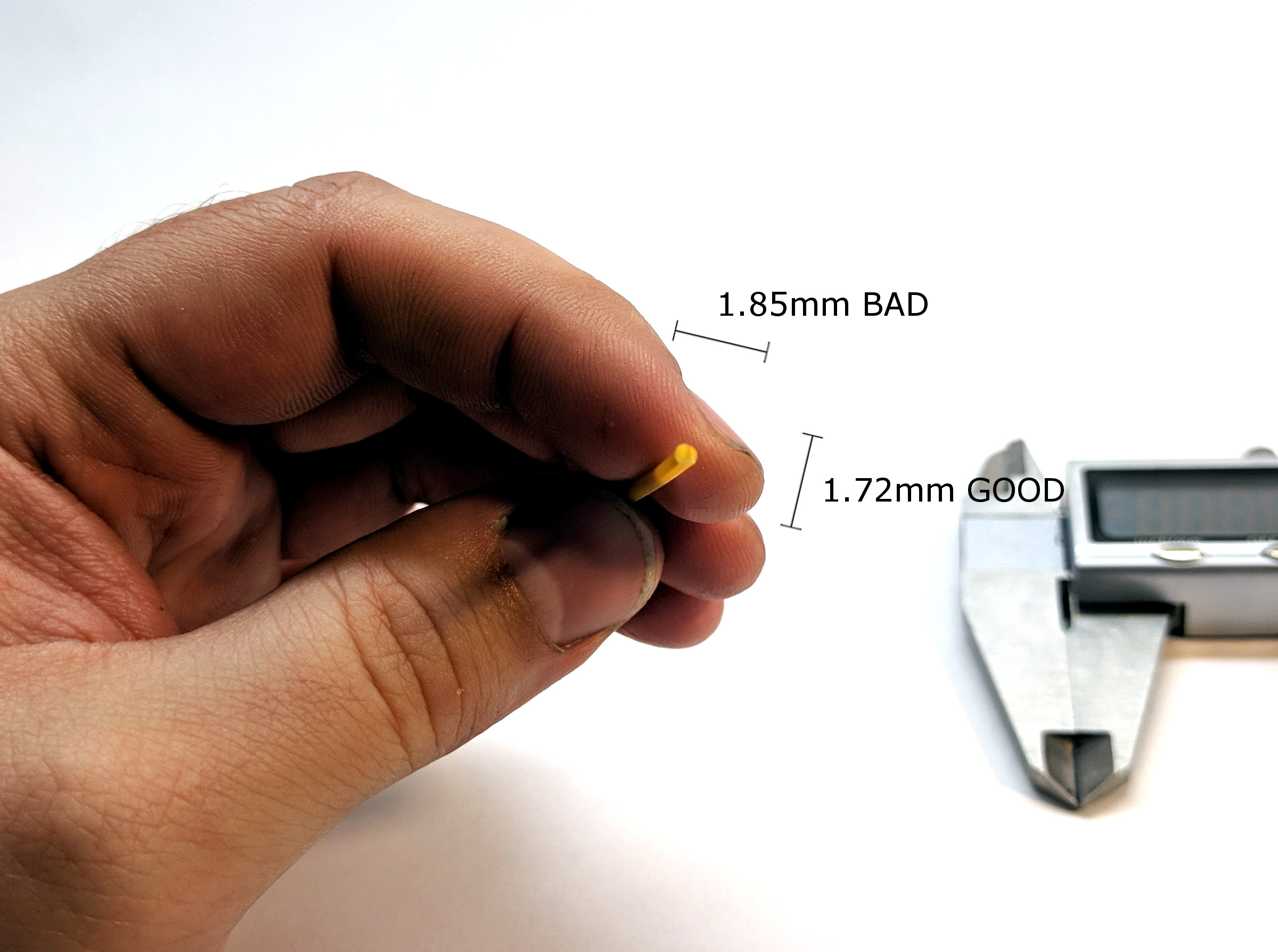

This is the tricky part. Many filaments will appear ok at first. The trouble is, they have a high degree of eccentricity, that is, they are out-of-round. To detect this, what you must do is take one measurement, then rotate the filament 90 degrees and take another measurement.

These pictures were taken from a piece of very cool looking pearlescent rainbow filament that we bought from Amazon. We loaded this into a reliable machine, equipped with an XS series Bowden tube, that we had previously used to print dozens of filaments without issue. Six hours into a 32 hour print, the machine clogged. We had to disconnect the ends of the tube and pull the filament out with a pair of pliars because it was lodged so tightly.

The first measurement we took was 1.72mm, so we thought the problem must be somewhere else. After rebuilding the entire hotend, we inserted the filament again, only to have it immidiately clog again.

Befuddled, we took another measurement from the same piece of filament, in the same spot. This time it measured 1.85mm. What was going on? It was out-of-round.

We attampted to print with it one more time, and this time it clogged so badly that we had to discard the tube.

The lesson here is that when you use a 1.9mm Bowden tube, you have to be very careful about what filaments you use. Just because it's expensive doesn't mean it's good quality. We do not want to endorse or poo-poo specific brands, but the filaments we have had zero issues with tend to be American or British brands like 3D Solutech, Atomic filament, and Spool.Works. We've also had good results with eSUN, as well as the more expensive names like Filamentum and Polyalchemy.

Frequently Asked Questions How To Install Choosing Your Tubing Selecting Your Fittings